Lambda sensor OZA685-WW1

Replacement for Bosch LSM 11

Article no. 118.02-7100

Lambda sensor NGK OZA685-WW1 for the biomass industry

Reducing emission values and increasing efficiency, these are among other things the requirements for a modern biomass heating system. Lambda sensor technology was developed in the 1970s and has been used as standard in the automotive sector since 1976. In the automotive sector, the lambda sensor regulates the ratio of fuel and air in order to achieve optimum efficiency with the lowest emissions. This principle of measuring the residual oxygen in the exhaust gas is also used when burning biomass (logs, wood chips, pellets). In order to permanently reduce emissions, regulation using a lambda sensor is state of the art.

The lambda sensor is a high-quality alternative to Bosch LSM 11.

Here you will find the right connection cable:

May you need a transmitter?

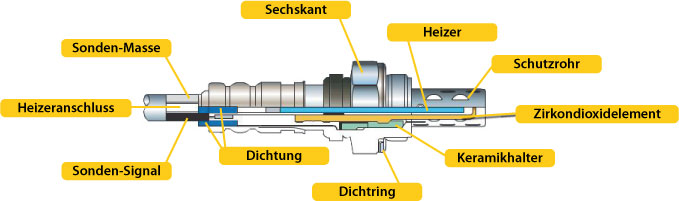

Construction of zirconia lambda sensor

zirconia element

The zircon element is a solid electrolyte. The heart of this lambda sensor is a finger-shaped ceramic that is hollow on the inside. In order to reach the desired operating temperature, a heater integrated into the element is switched on. Depending on the residual oxygen content in the exhaust gas, a high or low electrical voltage is generated in a complex process.

Protection tube

The metal protective tube protects the probe element from solid objects and dust in the exhaust gas.

Heater

An integrated heater ensures that the probe element reaches the required operating temperature very quickly and a constant mV signal is given after just a few minutes.

Ceramic holder

The ceramic holder holds the probe element and protects it from vibration.

Sealing ring

The sealing ring ensures a tight fit between the lambda probe and the threaded sleeve.

Hex

The lambda probe is screwed in with the hexagon. The correct tightening torque should be observed here.

Seal

To prevent moisture from penetrating the sensor, the cables are routed to the outside through a rubber seal. This seal is pressed over the sensor housing.

Heater connection

The heater of the lambda probe is supplied with power via these two white connections.

SensorMass

This gray line establishes the ground connection with the electronics.

Sensor Signal

The signal is routed to the electronics via this black wire.

Output line

faq

Yes. The sensor is a drop-in replacement and can be used as a high-quality alternative directly in place of Bosch LSM 11.

The OZA685-WW1 lambda sensor is suitable for biomass heating systems in which the Bosch LSM 11 was previously installed. It is ideal for existing systems where simple replacement without modifications is required.

Yes. The sensor is a drop-in replacement and can be used directly in place of the Bosch LSM 11 as a high-quality alternative.