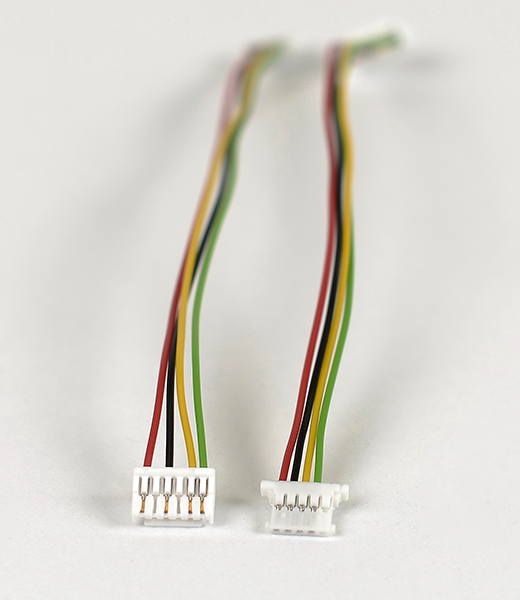

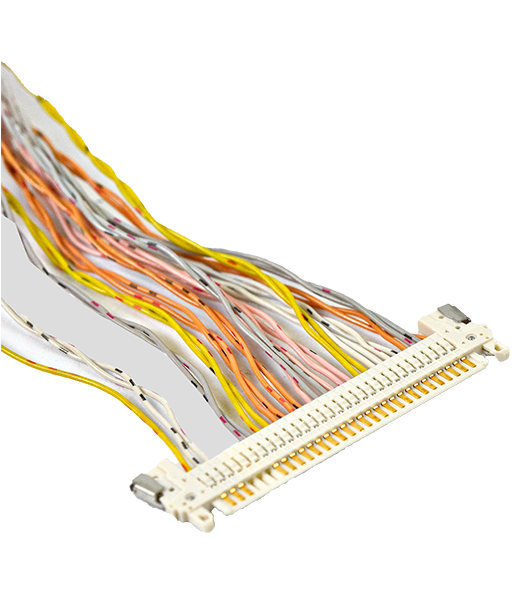

LVDS cable

individual LVDS cables

Produced according to your requirements

The English term Low Voltage Differential Signaling (LVDS) is an interface standard for high-speed data transmission.

An important area of application for LVDS is the digital control of liquid crystal displays (LCD). Many computer motherboards, which are intended to be installed together with the display in a common housing, often have a socket for a screen that can be connected via LVDS in addition to or instead of the usual VGA or DVI connection.

LVDS signals are used by many liquid crystal displays as an internal signal standard so that expensive converters can be dispensed with. On the computer side, the LVDS socket and its assignment are not standardized; on the display side, there are a few common sockets and signal assignments.

Thanks to our know-how and many years of experience, we can produce LVDS cables in a wide range of variants and designs.

Production process

The production process for our ready-made garments ensures problem-free production:

- Drawing/sketch/pattern from the customer

- Preparation of a detailed parts list and the production drawing

- Release by the customer

- Production of an initial sample including initial sample test report

- Start of series production of LVDS cables

High quality standards

We work according to the highest quality criteria in all service areas. Our “PeMaC” plant in Hungary has the ISO-Certificate according to 9001:2015, as well as the Certificate of Compliance for the use of our cable harnesses on the international market.

Backlight connection cable / LED backlight cable

LCD displays are usually illuminated by very thin fluorescent tubes powered by high voltage. LED backlighting is the more modern version of backlighting for LCD displays. The advantages compared to lighting with fluorescent tubes are

- Low energy consumption

- a much higher contrast

- more uniform illumination

TOUCH cable

Touchscreen displays are increasingly being used to control machines in industry (industrial PCs), particularly as they are less susceptible to dirt than other input devices such as keyboards.

Due to the large selection of touch panels and touch controllers, it is often difficult to connect them to each other. We will find the necessary cable and adapter solutions for you.These are produced by us on customer request.

Manufacturing process

From pre-assembled individual strands to complex cable harnesses, H&S Kabeltechnik GmbH develops and manufactures completely individually according to your requirements. With our state-of-the-art production facilities, our own production drawings and a team with many years of experience, we can respond to your wishes and requirements in the best possible way.

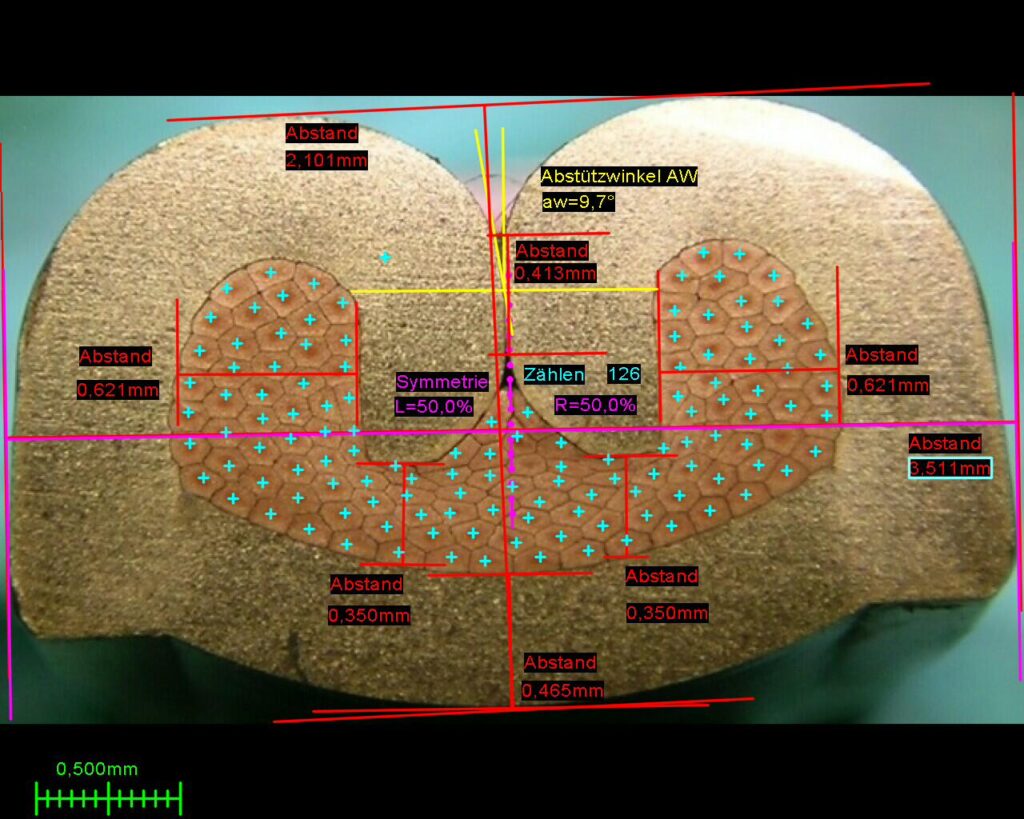

Precision is particularly important for LVDS cables as well as TOUCH and backlight connection cables. Komax’ crimp force monitoring (CFA) is a tried and tested solution for the early detection of crimp recommendations during production.

Perfect crimps thanks to crimp force monitoring

& Control by means of micrographs

Over 300 crimping tools

We crimp your desired assembly on over 300 different tools and create microsections. Everything is possible from 0.03mm² to 240mm².

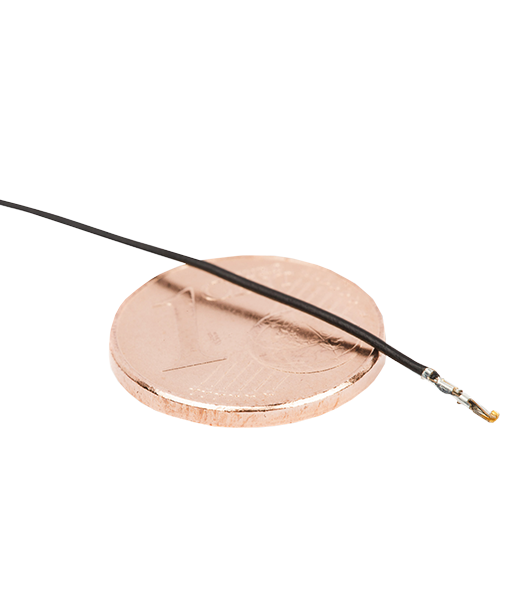

Crimp force monitoring systems measure and monitor crimping processes when crimping cable connections. These systems are necessary as it is no longer possible to visually inspect crimps in the AWG 30 – 26 range with the naked eye.

- AWG30 Outer cable diameter ca 0,3mm (7×0,102mm Average strands)

- AWG26 Outer cable diameter ca. 0,5mm (7×0,150mm Average strands)

Example crimp force monitoring system

Example micrograph of a crimp

The following errors are also determined using the two applications:

- Missing or sheared wires in the stranded wire

- Wrong crimp height

- Wire not completely in crimp

- Stripping too short

- Incorrect contact – Incorrect wire cross-section

- Relevant machine defects

- Tool wear and defects

Gamma 255

Fully automatic crimping machine for cables with small cross-sections

A key factor in our constant success is our proximity to our customers, to whom we make our expertise available with practical solutions. A good price-performance ratio in combination with high quality and absolute reliability characterises our work and is the solid basis for a successful cooperation.

We aim to promote our customers’ success by providing them with close support and advice on their tasks. No complex bureaucracy and quick decisions with sustainable implementation:

That is our recipe for success.

We look forward to receiving your enquiry and to producing your customised cable assembly.